Mark III & Manufacturing

Mark III is leading the evolution of construction.

You’ve heard us say it time and time again, but what does it really mean to lead the evolution of construction?

Simply put, we are dedicated to disrupting the construction industry with new ideas and different delivery methods. Innovation rarely happens in a bubble. Strategies and ideas that challenge the status quo often improve with collaboration and teamwork.

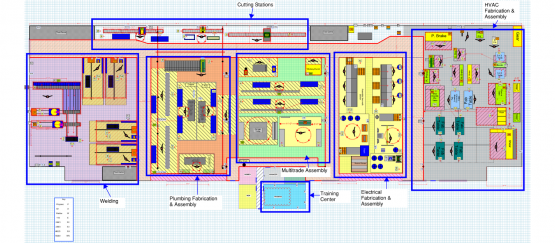

Embracing collaboration as a key input for successful innovation allows our team to covert concepts into results. We believe there is a better way to build that will save time and money for owners and contractors alike. To support that belief, in August 2019, Mark III opened a 24k state-of-the-art MEP Manufacturing Facility in Sacramento, CA. It is the first of its kind in the region and houses five trades under one roof – electrical, HVAC, plumbing, process piping, and metal-stud framing.

Production Capabilities

Facility Features

- 24 K SF

- 93 individual pieces of equipment

- 3.7 acres for future expansion and growth

Manufacturing & Waste

The facility serves as a hub for multi-trade manufacturing, allowing our trade teams to create highly efficient prefabricated spools, parts, and assemblies. According to the Modular Building Institute, construction and demolition waste are the single largest source of waste in the U.S., producing more than 135 million tons of debris each year. Manufacturing works to reduce and eliminate waste through the following functions:

- Defects

- Overproduction

- Waiting

- Poor utilization of talent

- Excessive transportation

- Excessive inventory

- Excessive footsteps

- Over-processing

Multi-Trade

Five trades are performed under one roof:

- Electrical

- HVAC

- Plumbing

- Process piping

- Metal-stud framing

Standard Assemblies

We approach every aspect of our business with a manufacturing and lean mentality. In tandem with our fabrication division, Mark III’s trade specialists have developed and standardized MEP in-wall and MEP overhead assemblies which are compiled into a library-like catalog and used as a resource for all projects. This library allows foremen to pre-plan and order assemblies for their projects, which saves time during the on-site installation.

Learn how prefabrication and manufacturing reduced hours by 45.23% on a recent project in Fresno.

Work Cells

Mark III utilized 5S Methodology when planning the layout of the facility to maximize efficiency and effectiveness. There are over 60 work cells strategically laid out to allow for seamless change-over between trades and tasks.

Work cells are adjusted as needed, but always at the end of the day so work can begin quickly and efficiently the following workday.

MEP Wall Panels

Our manufactured metal stud-framed interior wall panels are delivered to the site complete with all mechanical, electrical, and plumbing in-wall inclusive to the assembly. Panels are produced as a standalone product or combined with a full MEP package to furnish a seamless and quick install of interior walls.

The use of manufactured wall panels complete with multi-trade utilities simplifies the way complex projects are delivered. Building with manufactured parts allows construction to begin before field conditions permit, reducing the overall construction schedule. Manufacturing capitalizes on standardization, repeatability, and predictability to increase production and efficiency.

To learn more about how Mark III is transforming the way construction projects are built, check out our project mountain videos here.

The Future

Training

Did you know that 25% of Mark III’s employees either are working or have worked/trained in our MEP Manufacturing Facility (formerly referred to as fabrication shop)?

The facility includes a dedicated training space for the next generation of tradesmen and women. Our MEP Manufacturing Facility is the place where many Mark III employees begin their journey with Mark III and often times the construction industry as a whole. Apprentices can earn welding certifications in-house, gain experience across multiple trades, and more.

Expansion

Looking ahead, Mark III has secured 3.7 acres for future growth and expansion.