With decades-long experience in the industry, M3 can attest to the devastating consequences of mechanical, electrical, and plumbing (MEP) system failures, in high-reliability environments such as hospitals, data centers, biotech labs, and manufacturing plants. While no direct figures are publicly available quantifying financial losses in mission-critical facilities, documented operational expenditures and failures suggest that financial impacts from MEP-related downtime ranges from tens to hundreds of millions annually in California alone.

Financial impact only tells part of the story. Failing to manage MEP emergencies can lead to data loss, product damage, and in the worst cases, loss of life. Take, for example, what happened on the afternoon of January 16, 2025, when a fire broke out at a storage facility in Monterey County, California, forcing the evacuation of 1,200 to 1,500 residents. There were no fatalities in the accident, but the outcome could have been far more serious.

Fortunately, these situations are entirely preventable—with 24/7 emergency MEP services playing a critical role when it matters most. At M3, the safety of our clients and their establishments are at the core of everything we do. Our customer-focused certified technicians provide our clients with solutions to all their mechanical/HVAC, electrical, plumbing, and fire alarm/monitoring needs 24 hours a day, 7 days a week.

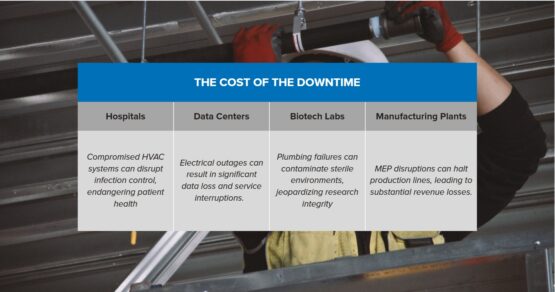

The Cost of Downtime

Mission-critical facilities depend on the flawless performance of their MEP systems. A single downtime can be costly:

- Hospitals: Compromised HVAC systems can disrupt infection control, endangering patient health.

- Data Centers: Electrical outages can result in significant data loss and service interruptions.

- Biotech Labs: Plumbing failures can contaminate sterile environments, jeopardizing research integrity.

- Manufacturing Plants: MEP disruptions can halt production lines, leading to substantial revenue losses.

What Emergency MEP Services Cover

M3’s 24/7 Emergency MEP Services cover a comprehensive range of mechanical, electrical, and plumbing capabilities, including general maintenance repairs. Our dedicated service team is available around the clock to respond to your emergencies, ensuring continuous support for our clients’ critical systems. This includes performing emergency repairs and maintenance to keep facilities operational without significant downtime. From initial construction and design-build to ongoing service and preventative maintenance, we guarantee:

- Fast response HVAC system repairs and maintenance

- Plumbing system repairs

- Electrical system troubleshooting and repairs

- General maintenance services to address urgent facility issues

Our 24/7 availability ensures that our clients receive timely and expert response to emergencies affecting their building systems. M3’s integrated approach means working with a single company for all your MEP needs, reducing complexity and improving response efficiency during emergencies.

Why California Facilities Face Unique Risks

Due to its climate, population, and geography, California faces complex environmental and infrastructural challenges:

- Power grid instability – Rolling blackouts and energy shortages threaten operational continuity.

- Heatwaves – Extreme temperatures increase HVAC system strain, leading to higher failure rates.

- Seismic activity – Earthquakes pose structural and electrical risks that demand immediate response.

- Wildfires – Smoke and fire damage can compromise air filtration and electrical systems.

- Aging infrastructure – Older buildings require specialized MEP interventions to maintain compliance and reliability.

Facilities in California must prioritize rapid-response 24/7 MEP services to navigate these environmental and infrastructural challenges effectively.

Proactive Measures to Prevent Catastrophic Failures and Downtime

While emergency MEP services are essential for rapid response, the most resilient mission-critical facilities invest in proactive maintenance strategies to prevent emergencies before they occur. Two of the most effective preventative measures are annual thermographic (infrared) scanning of electrical systems and regular hydro jetting and descaling of plumbing lines.

Annual Thermographic (IR) Scanning

Electrical faults are a leading cause of downtime and fire risk in mission-critical environments. Many of these issues, such as loose connections, overloaded circuits, or failing components, develop out of sight and can go undetected until they trigger a failure. Annual thermographic (IR) scanning uses advanced infrared cameras to detect abnormal heat signatures in electrical panels, switchgear, and componentry.

Benefits of IR Scanning:

- Early Detection: Identifies “hot spots” and electrical anomalies before they escalate into failures or fires.

- Non-Invasive: Inspections can be conducted without shutting down equipment, minimizing operational disruption.

- Regulatory Compliance: Many insurance providers and regulatory bodies recommend or require annual IR scans for high-reliability facilities.

- Cost Savings: Proactive repairs based on IR findings are far less expensive than emergency repairs following a catastrophic failure.

Hydro Jetting

Plumbing failures can cause significant operational disruptions, water damage, and contamination, especially in healthcare, biotech, and manufacturing facilities. Over time, mineral scale, grease, and debris accumulate inside pipes, leading to blockages, reduced flow, and even pipe bursts.

Benefits of Hydro Jetting:

- Hydro Jetting: Uses high-pressure water streams to clear blockages and thoroughly clean pipe interiors.

- Descaling: Removes mineral buildup that can constrict flow and corrode pipes.

- Preventative Maintenance: Annual or semi-annual service dramatically reduces the risk of unexpected plumbing failures and costly downtime.

- Improved Hygiene: Especially critical in environments where water quality and sanitation are paramount.

Integrating Proactive Maintenance into Your Facility Plan

By incorporating annual IR scanning and scheduled hydro jetting/descaling into your facility’s maintenance program, you significantly lower the risk of unplanned outages, equipment damage, and costly repairs. These proactive measures, combined with 24/7 emergency MEP services, create a comprehensive approach to operational resilience for mission-critical environments.

Protect Yourself and Your Business Today

For mission-critical facilities, emergency MEP services are not optional- they are an absolute necessity, providing vital protection against costly and potentially dangerous downtime.

At M3 Service, we understand that every second counts, which is why we are dedicated to delivering:

- 24/7 Emergency Hotline: Rapid, expert assistance whenever you need it, day or night.

- Readiness Consultations: Proactive evaluations designed to uncover vulnerabilities before they become emergencies.

- Comprehensive Service Agreements: Customized, reliable solutions meticulously crafted to meet the unique demands of your facility.

Don’t wait for a crisis to act. Contact us today to safeguard your facility against unforeseen MEP challenges.